3.1 Liter V6 Engine Problems; All Explained

The 3.1-liter V6 engine has been a workhorse for various vehicles over the years, known for its performance and reliability. However, like any other mechanical component, it is not immune to issues.

In this blog post, we will delve into some of the most common problems that plague the 3.1-liter V6 engine and discuss the importance of addressing these issues promptly to ensure the longevity and optimal performance of your vehicle.

Table of Contents

Is the 3.1 V6 a good engine?

The 3.1-liter V6 engine has been used in various vehicles over the years and has earned a reputation for its durability and performance. However, whether it is considered a “good” engine depends on several factors, including the specific model, year, and application in which it is used, as well as individual experiences and preferences.

Here are some aspects to consider when evaluating the 3.1-liter V6 engine:

- Reliability: The 3.1 V6 is generally known for its reliability and longevity. Many drivers have reported driving vehicles equipped with this engine for high mileage without major issues.

- Performance: While the 3.1 V6 may not be the most powerful engine in its class, it has provided satisfactory performance for many vehicles. It’s important to note that the perception of “good” performance can vary depending on the vehicle’s intended use.

- Fuel Efficiency: The fuel efficiency of the 3.1 V6 can vary based on factors such as vehicle weight, aerodynamics, and driving conditions. In some cases, it might be considered relatively fuel-efficient, but advancements in engine technology over the years have led to more efficient options.

- Maintenance and Repairs: Like any engine, the 3.1 V6 requires regular maintenance to ensure its continued reliability and performance. Some common issues have been identified, as discussed in the outline you provided earlier, but timely maintenance and addressing problems can help mitigate these issues.

- Availability of Parts: Since the 3.1 V6 has been used in various vehicles, parts availability might not be a significant concern. However, it’s always a good idea to check the availability of replacement parts before investing in a vehicle with this engine.

- Age and Model: Keep in mind that the age of the engine and the specific vehicle model it’s used in can impact its overall performance and reliability. Newer models may have benefited from design improvements and technological advancements.

Whether the 3.1 V6 is a “good” engine depends on your specific needs and expectations. If you’re considering a vehicle with this engine, it’s recommended to research the particular make, model, and year of the vehicle, read owner reviews, and consult with mechanics or automotive experts to make an informed decision based on your priorities and preferences.

3.1l V6 Engine Specs

| Parameter | Description | Value Range or Specification |

|---|---|---|

| Type | Engine Type | 60 degree V6 |

| Displacement | Engine Displacement | 3.1L |

| RPO | Engine RPO Code | LH0 |

| Bore | Cylinder Bore Diameter | 89.0 mm |

| Stroke | Crankshaft Stroke Length | 84.0 mm |

| Deck Height | Deck Height | 224 mm |

| Compression Ratio | Compression Ratio | 8.8:1 |

| Firing Order | Cylinder Firing Order | 1-2-3-4-5-6 |

| Oil Pressure | Oil Pressure Specifications | 69 kPa @ 500 RPM; 205-380 kPa @ 2000 RPM (10 psi @ 500 RPM; 30-55 psi @ 2000 RPM) |

| Cylinder Bore | ||

| – Diameter | Cylinder Bore Diameter Range | 89.02-89.03 mm |

| – Out of Round | Maximum Out of Round | 0.013 mm (Maximum) |

| – Taper – Thrust Side | Maximum Taper – Thrust Side | 0.013 mm (Maximum) |

| Maximum Deck Warpage | Maximum Deck Warpage | 0.13 mm |

| Piston | ||

| – Clearance | Piston Clearance Range | 0.023-0.056 mm |

| Piston Ring | ||

| – COMPRESSION | ||

| – Groove Clearance | Top & Second Groove Clearance Range | 0.051-0.089 mm |

| – Gap | Top & Second Gap Range | 0.25-0.51 mm (Top); 0.51-0.071 mm (Second) |

| – OIL | ||

| – Groove Clearance | Oil Groove Clearance | 0.20 mm (Maximum) |

| – Gap | Oil Gap Range | 0.25-0.76 mm |

| Piston Pin | ||

| – Diameter | Piston Pin Diameter Range | 22.992-22.997 mm |

| – Clearance | Piston Pin Clearance Range | 0.010-0.020 mm |

| – Fit in Rod | Piston Pin Fit in Rod Range | 0.018-0.046 mm |

| Crankshaft | ||

| – Main | ||

| – Journal Diameter | Main Journal Diameter Range | 67.241-67.267 mm |

| – Taper | Maximum Main Journal Taper | 0.005 mm (Maximum) |

| – Out Of Round | Maximum Main Journal Out of Round | 0.005 mm (Maximum) |

| – Main Bearing Clearance | Main Bearing Clearance Range | 0.028-0.094 mm |

| – Crankshaft End Play | Crankshaft End Play Range | 0.05-0.2 mm |

| – Crankpin | ||

| – Diameter | Crankpin Diameter Range | 50.757-50.784 mm |

| – Taper | Maximum Crankpin Taper | 0.005 mm (Maximum) |

| – Out of Round | Maximum Crankpin Out of Round | 0.005 mm (Maximum) |

| – Rod Bearing Clearance | Rod Bearing Clearance Range | 0.028-0.094 mm |

| – Rod Side Clearance | Rod Side Clearance Range | 0.18-0.44 mm |

| Camshaft | ||

| – Lift | Camshaft Lift | Intake: 6.68 mm; Exhaust: 6.93 mm |

| – Journal Diameter | Camshaft Journal Diameter Range | Journals 1 & 4: 47.45-47.80 mm |

| – Journal Clearance | Camshaft Journal Clearance Range | 0.03-0.10 mm |

| Valve System | ||

| – Lifter | Valve Lifter Type | Hydraulic |

| – Rocker Arm Ratio | Rocker Arm Ratio | 1.50:1 |

| – Valve Lash | Valve Lash Specifications | Intake: 1-1/2 Turns Down from Zero Lash; Exhaust: 1-1/2 Turns Down from Zero Lash |

| – Face Angle (Intake & Exhaust) | Valve Face Angle (Intake & Exhaust) | 45 degrees |

| – Seat Angle (Intake & Exhaust) | Valve Seat Angle (Intake & Exhaust) | 46 degrees |

| – Margin | Valve Margin | Exhaust: 1.55-1.85 mm; Intake: 1.70-2.01 mm |

| – Runout | Valve Runout | 0.25 mm |

| – Stem Clearance | Valve Stem Clearance Range | 0.2-0.8 mm |

| Valve Spring | ||

| – Free Length | Valve Spring Free Length | 48.5 mm |

| – Pressure (Kg @ mm) | Valve Spring Pressure | Closed: 41 @ 43.2 mm; Open: 98 @ 32.8 mm |

| – Installed Height | Valve Spring Installed Height | 39.9 mm |

| Valve Spring Damper | ||

| – Free Length | Valve Spring Damper Free Length | 48.5 mm |

| – Approx # of Coils | Number of Coils | 4 coils |

What are 3.1 Liter V6 Engine problems?

01. Common Issues

- Oil Leaks and Gasket Failures

Gasket failures within the engine can lead to oil leaks, which can significantly impact engine performance. These leaks result in oil wastage, leading to decreased lubrication, potentially causing friction and overheating.

If left unchecked, gasket failures can escalate into more severe engine problems. To prevent further damage, it’s crucial to promptly identify and address oil leaks through regular inspections and maintenance.

- Overheating and Cooling System Challenges

The cooling system is vital in maintaining the engine’s optimal operating temperature. Overheating can occur for various reasons, such as a malfunctioning thermostat, radiator issues, or coolant leaks.

Over time, these problems can lead to engine damage and decreased efficiency. Regular maintenance, including checking coolant levels, inspecting hoses, and servicing the radiator, is essential to prevent overheating and ensure the engine’s longevity.

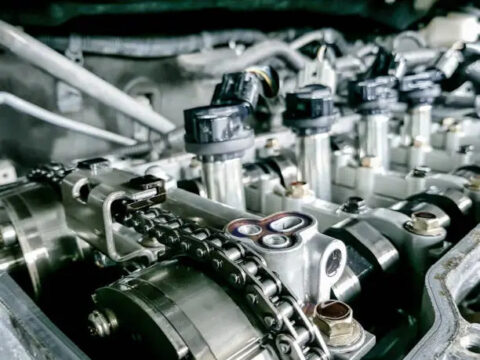

02. Timing Chain Tensioner Problems

The timing chain tensioner is a crucial component that maintains proper timing synchronization within the engine. It ensures that the camshaft and crankshaft are in sync, allowing for smooth engine operation.

However, tensioner problems can disrupt this synchronization, leading to poor engine performance and potential damage.

- Symptoms of a Failing Tensioner

A failing timing chain tensioner can result in rattling noises from the engine, decreased power, and poor fuel efficiency. If not addressed, it can cause the timing chain to slip or jump teeth, leading to catastrophic engine failure.

Regular maintenance and prompt replacement of a failing tensioner can prevent these issues and maintain the engine’s performance.

GM 3.4L V6 Engine Problems; Everything You Need To Know

ENGINERIDES.COM

03. Misfire and Rough Idling

Engine misfires can occur due to various reasons, including faulty spark plugs, ignition coils, or fuel injectors.

These issues can lead to rough idling, decreased power, and increased emissions. Ignoring misfires can result in long-term damage to the engine components.

- Addressing Rough Idling

Proper diagnosis of the underlying cause is essential to address rough idling. Regularly checking and replacing spark plugs, ignition coils, and maintaining a clean fuel system can help prevent misfires and ensure a smoother engine operation.

04. Faulty Fuel Injectors

Fuel injectors play a crucial role in delivering the right amount of fuel to the combustion chamber. When these injectors malfunction, it can lead to poor fuel economy, decreased power, and increased emissions.

- Signs of Faulty Injectors

Signs of faulty fuel injectors include rough idling, poor acceleration, and increased fuel consumption. Regular maintenance, including cleaning or replacing injectors, can prevent these issues and ensure proper engine performance.

05. Intake Manifold Gasket Failures

The intake manifold gasket seals the connection between the intake manifold and the engine block, ensuring proper air-fuel mixture for combustion.

Gasket failures can lead to vacuum leaks, affecting engine performance and fuel efficiency.

- B. Detecting Gasket Failures

Common signs of intake manifold gasket failures include rough idling, misfires, and poor acceleration. Regular inspection and timely replacement of faulty gaskets can prevent these issues from escalating.

06. Electrical System Glitches

Electrical problems can disrupt various engine functions, leading to poor performance, starting issues, and malfunctions in vital systems such as ignition and fuel injection.

Thoroughly inspecting the electrical system, checking for loose connections, damaged wires, and malfunctioning sensors can help identify and address electrical glitches, ensuring optimal engine performance.

07. Transmission and Engine Interface

Transmission issues can have a direct impact on engine performance. Problems such as slipping gears or delayed shifts can result in decreased power delivery and fuel efficiency.

It’s important to coordinate repairs between the engine and transmission, as these systems are interconnected. Addressing transmission problems promptly can prevent potential damage to the engine and ensure smooth operation.

Why Lexus IS 250 Tires Have Different Sizes: Explained Simply

ENGINERIDES.COM

Conclusion

The 3.1-liter V6 engine, while robust and dependable, can face a range of issues over time. Regular maintenance, prompt diagnosis, and addressing problems as they arise are essential to keep the engine running smoothly and extend its lifespan.

By understanding and proactively dealing with these common problems, you can enjoy optimal performance and reliability from your vehicle’s engine for years to come.

One Comment